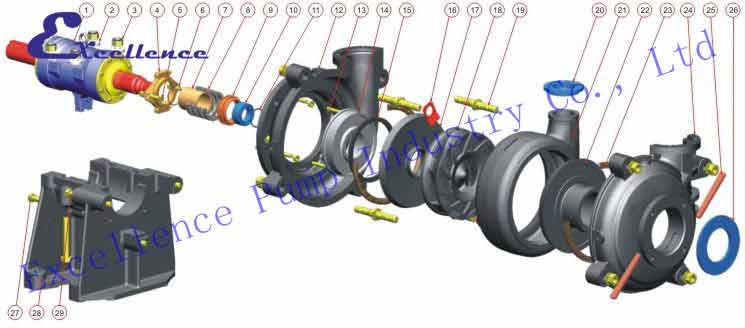

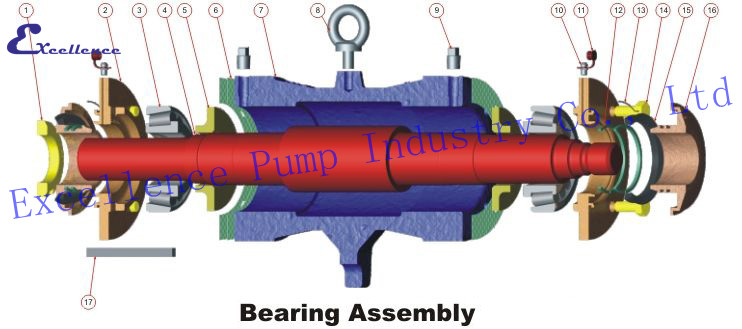

1.Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and Throatbush and can be removed completely;

2.Interchangeable anti-abrasive wet parts made of high-chrome alloys;

3.The discharge direction can be oriented to any eight positions at the interval of 45 degrees;

4.Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc;

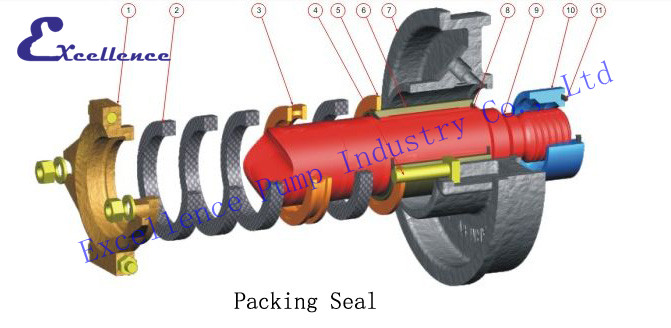

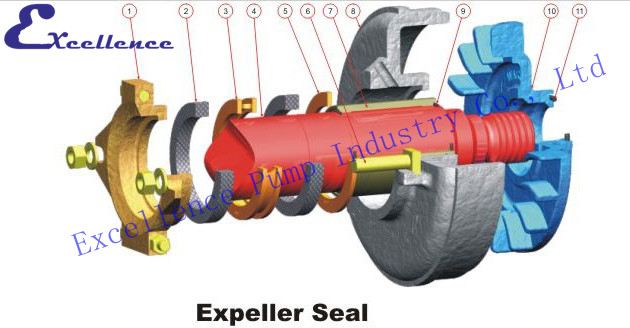

5.The shaft seal can be packing seal, expeller seal or mechanical seal;

ELM-50B

11.5-65 m³/h

8.5-46 m

15 Kw

1400-2800

2.5-5.5

ELM-75C

21.6-136.8 m³/h

7-46.4 m

30 Kw

900-2400

3-6

ELM-100D

46.8-324 m³/h

7-48.3 m

60 Kw

800-1800

2.5-6

ELM-150E

126-568.8 m³/h

10.5-52 m

120 Kw

800-1500

2.5-6

ELM-300S

568-2538 m³/h

8-60 m

560 Kw

400-950

3-8

ELM-350S

650-2800 m³/h

10-59 m

560 Kw

400-840

3-10

ELM-400S

756-3312 m³/h

7-37.5 m

560 Kw

300-600

2-8

ELM-450ST

1080-4356 m³/h

9-40 m

560 Kw

300-350

3-10

ELM-550TU

1980-7920 m³/h

9-50 m

1200 Kw

250-475

4-10

Centrifugal seal with packing seal

Upright

Customized

Green

Fumigation-free wooden packaging